What does lean management mean?

Lean management is an approach to process optimization in which waste is minimized and processes are harmonized. The term Lean Management originates as "lean management" from the English language and can be translated into German as "schlankes Management". This method originated in the Toyota production system, which focuses on creating stable process organizations. These form the basis of the level of quality achieved in Toyata products.

The aim of lean management is to avoid all forms of waste, errors and unnecessary costs in all areas of the company, while achieving the best possible quality. All activities required to create value are to be optimally coordinated and superfluous activities eliminated. To achieve this, both the customer perspective must be considered in order to be able to implement customer wishes for availability, individuality, quality and pricing, and the company perspective, which must function profitably and improve competitiveness.

The implementation of process definitions, interface descriptions, clear responsibility structures, early reactions to errors and simple organizational methods result in stable processes with a high level of customer orientation.

In the literature according to Graf-Götz and Glatz, 10 design approaches can be found for the implementation of lean management:

1. orientation of all activities to the customer (customer orientation)

2. concentration on the company's own strengths

3. optimization of business processes

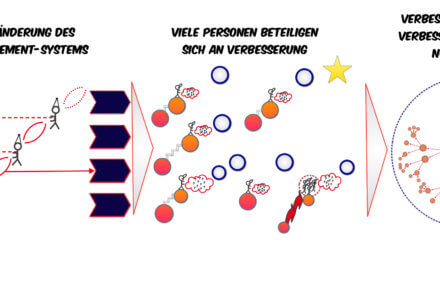

4. continuous improvement of quality (continuous improvement process, CIP)

5. Internal customer orientation as a corporate mission statement

6. Personal responsibility, empowerment and teamwork

7. Decentralized, customer-oriented structures

8. Leadership is service to the employee

9. Open information and feedback processes 10. Attitude and culture change in the company (Kaikaku)