Process optimisation in injection moulding: efficient set-up of colour mixing systems

Process station for dosing, mixing and colouring plastic granulate

The injection moulding process is a complex task in which efficiency and flexibility play a decisive role. In particular, the set-up of colour mixing systems used for colouring neutral plastic granulate is a challenge for many companies. We will show you how a clever solution using a mobile process station can solve common problems.

Get in touch with us:

The challenge: Greater effort during set-up

Many production companies are facing similar difficulties:

- High set-up effort: A colour mixing system consists of several components, the assembly of which is time-consuming.

- Awkward walking routes: Transporting and setting up the parts requires a lot of unnecessary travelling.

- Lack of space: The space around the injection moulding machine is often limited, which makes working even more difficult.

The solution: Mobile process station for colour mixing systems

These problems can be effectively solved with a mobile process station. This innovative solution combines all the necessary tools in a compact, mobile unit that can be positioned directly on the injection moulding machine.

The benefits at a glance:

- More efficient set-up: All components of the colour mixing system are located on a trolley and can be brought directly to the machine. This saves time and significantly reduces walking distances.

- Integrated tools: The process station contains all the tools required for set-up. This keeps everything ready to hand in one place.

- Ergonomic working: The system controls are mounted on the trolley at an optimum working height. This makes it easier to operate and read the display.

- Space-saving design: The compact design of the process station ensures that space requirements are minimised - perfect for tight production environments.

Customer benefits: Time savings and productivity

The use of a mobile process station offers considerable advantages for companies in the injection moulding sector. The significantly shorter set-up time increases productivity, while the ergonomic design reduces the strain on employees. At the same time, the

This space-saving solution allows more flexible utilisation of the production area.

Conclusion

For anyone looking for efficient solutions for the injection moulding sector, the mobile process island offers real added value. This solution can effectively solve common problems when setting up colour mixing systems.

Do you have any questions or would you like to find out more about the mobile process station?

Contact us - we will be happy to advise you!

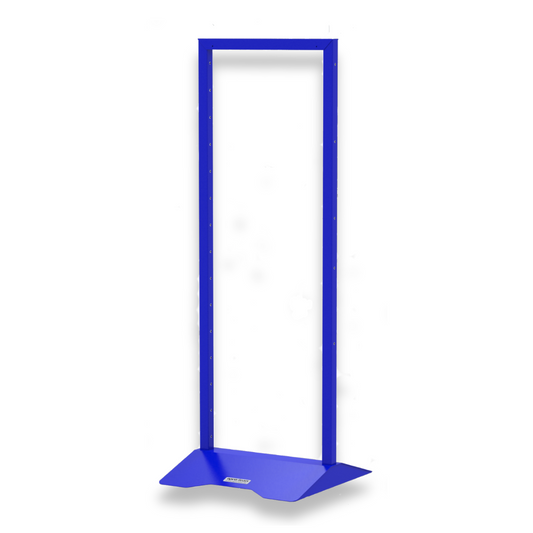

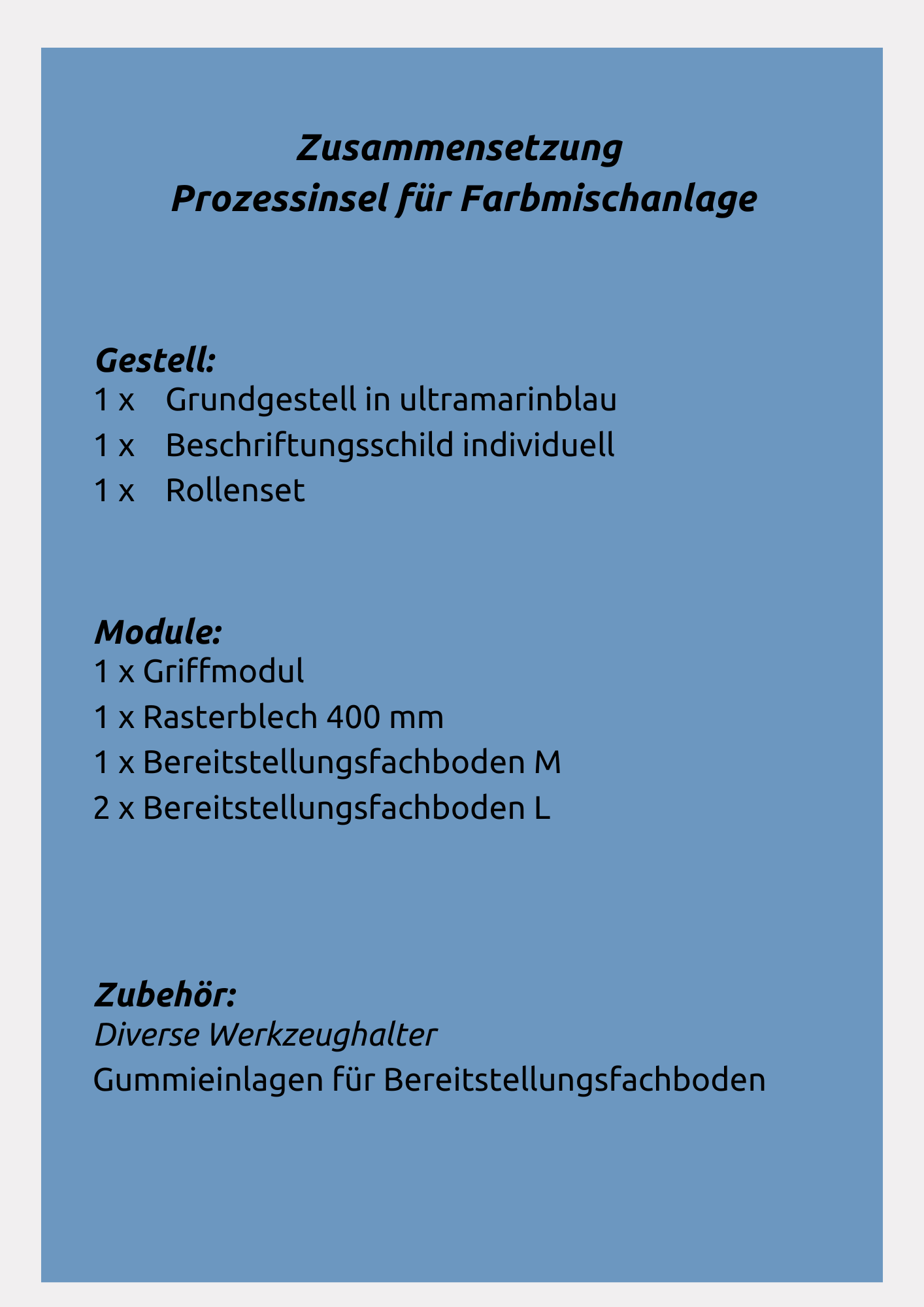

Composition of the set-up station for colour mixing device

-

Basic frames

Regular price From €317,50 EURRegular priceUnit price / per -

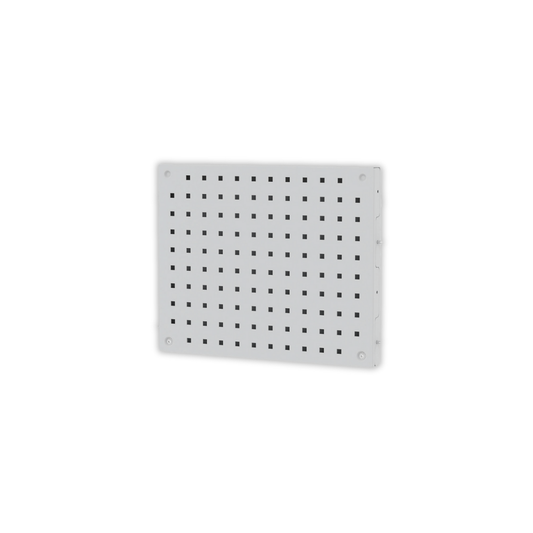

Grid plate 400 mm

Regular price €82,75 EURRegular priceUnit price / per -

Supply shelf M

Regular price €71,40 EURRegular priceUnit price / per -

Supply shelf L

Regular price €68,65 EURRegular priceUnit price / per -

Handle module

Regular price €9,30 EURRegular priceUnit price / per -

Labeling sets Individual text

Regular price €79,65 EURRegular priceUnit price / per -

Roller set

Regular price €79,65 EURRegular priceUnit price / per

1

/

of

7