Process station in electrode production: increasing efficiency through 5S in toolmaking

Get in touch with us:

The challenge of electrode construction

There were a number of challenges before the process station was introduced:

- Electrodes were spread across shelves, drawers and even workbenches.

- There was no centralised storage at the eroding machine, which caused search times and mix-ups.

- Resources and tools were not always immediately available.

Especially with complex injection moulds, where several electrodes are often used, this meant a significant reduction in productivity.

The solution: a mobile process station

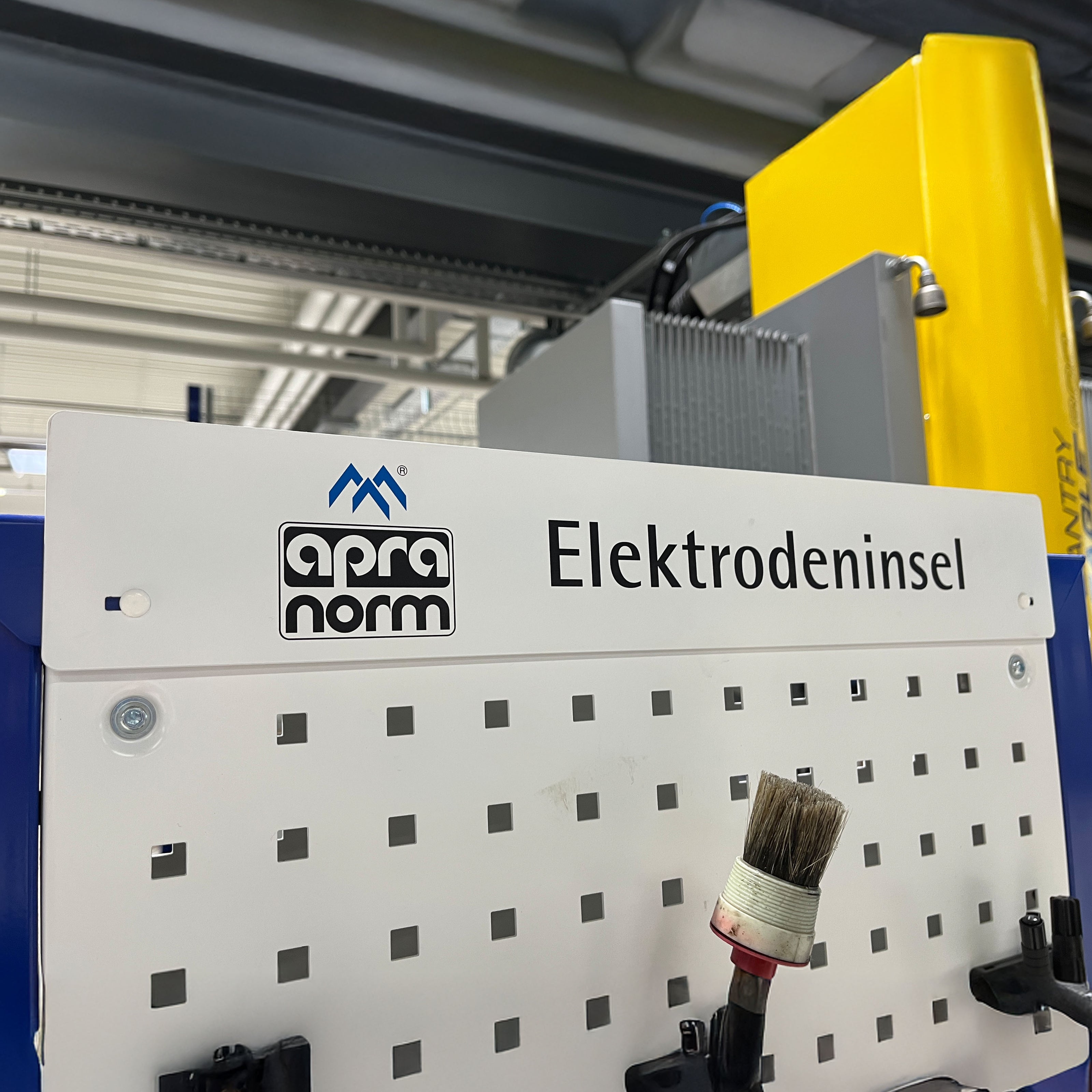

Our process station was specially developed for use on milling and eroding machines in toolmaking.

developed. It offers an optimum combination of organisation, flexibility and efficiency.

The most important features at a glance:

- Centralised storage of all electrodes:

The process station keeps all current copper electrodes clearly organised directly at the machine. - Transportable:

The mobile station can be easily moved between milling and eroding machines, which optimises the material flow. - Integrated aids:

Tools and aids are always to hand, which reduces interruptions to work. - Dispenser for semi-finished copper products:

Standardised copper pieces are available for the construction of new electrodes - at any time and in the right quantity. - Precisely fitting sheet metal inserts:

These ensure that the electrodes and tools are precisely positioned to prevent damage and mix-ups.

Increased efficiency through the 5S method

The introduction of the process island is based on the proven 5S methodwhich ensures order and

structure in the workplace:

- Sort: Superfluous items have been removed in order to focus on the essentials.

- Systematise: Electrodes, tools and aids were organised at fixed locations.

- Cleaning: A clean workplace is the basis for precision and safety.

- Standardise: Processes and workflows have been standardised to minimise search times and errors.

- Self-discipline: Regular checks ensure that order is maintained.

By consistently applying these principles, we have not only been able to increase efficiency, but also improve employee job satisfaction.

The customer benefits: More overview and flexibility

The process station offers clear advantages for toolmakers and lean managers:

- Time saving: All electrodes and aids are quickly available, which minimises search times.

- Flexibility: The mobile solution enables easy adaptation to changing workstations.

- Quality: Organisation and clarity contribute to precise work and avoid errors.

- Sustainability: The dispenser for standardised semi-finished products promotes the efficient use of materials.

Conclusion: Structured workstations for maximum productivity

The introduction of the mobile process station in electrode production shows how important structured workstations are for success in toolmaking. With the support of the 5S method

has created a system that not only increases efficiency, but also makes day-to-day work easier for colleagues.

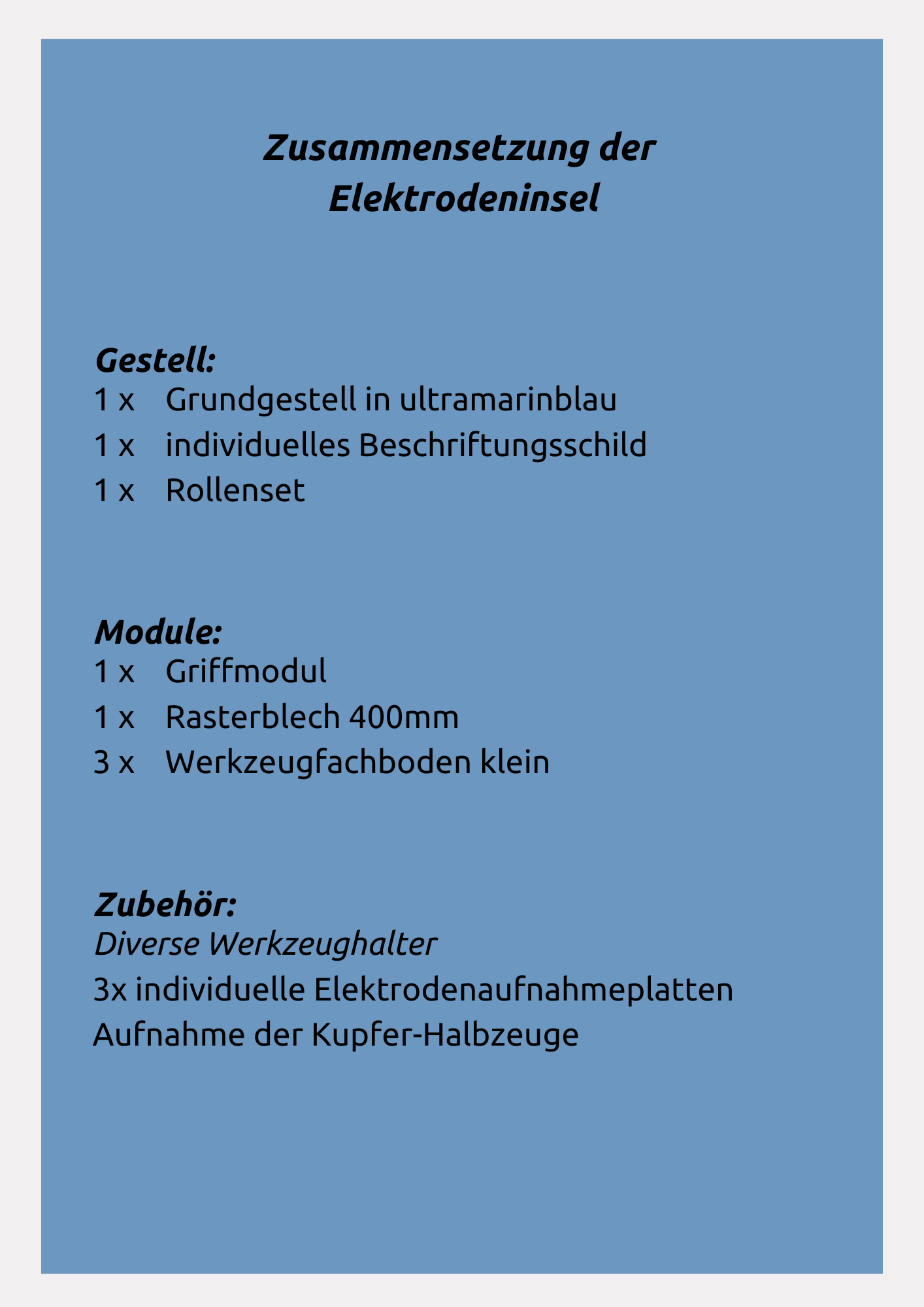

Zusammensetzung der Elektrodeninsel

-

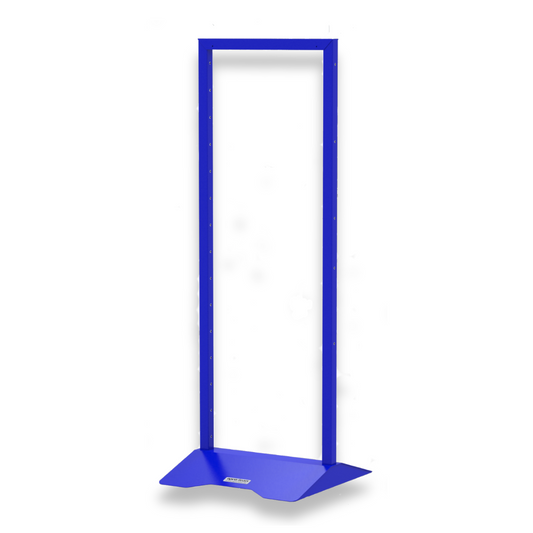

Basic frames

Regular price From €317,50 EURRegular priceUnit price / per -

Grid plate 400 mm

Regular price €82,75 EURRegular priceUnit price / per -

Labeling sets Individual text

Regular price €79,65 EURRegular priceUnit price / per -

Roller set

Regular price €79,65 EURRegular priceUnit price / per -

Handle module

Regular price €9,30 EURRegular priceUnit price / per

1

/

of

5