Efficient set-up of injection moulds

Long set-up times and disorganised work processes are a common problem in injection moulding production, causing not only efficiency losses but also unnecessary costs. In this article, we use a specific example to show you how targeted process optimisation using SMED analysis and the 5S method can achieve impressive results.

Get in contact with us:

The challenge: Minimising set-up times and search effort

Our customer's injection moulding production was faced with the following challenges:

- Long set-up times: Change processes took much longer than necessary.

- Unnecessary tool surplus: Too many or defective tools made it difficult to maintain an overview.

- High search effort: Tools were scattered in drawers and hard to find.

- No standards: Differently equipped tool trolleys and equipment led to inconsistent working methods.

These problems not only led to production delays, but also to frustration among employees.

The solution: a standardised rescue vehicle

By using the SMED-Analyse (Single-Minute Exchange of Die) and the 5S-Methodset-up has been systematically optimised:

- Analysis of the work process: First, the set-up times were analysed and all the tools required were identified.

- Eliminate the superfluous: Unnecessary or defective tools were consistently removed.

- Standardisierung: A standardised rescue vehicle was developed and equipped with all the relevant tools.

- Visual order: Each tool is clearly visible to eliminate search times.

The key to efficiency lay in a individual apra-lean set-up vehiclewhich has been specially adapted to the needs of employees.

The customer benefit: More efficiency in the setup process

The advantages of this optimization speak for themselves:

- Reduced setup times: All tools are within reach, which significantly accelerates the changeover processes.

- Standardized working method: Every employee can work efficiently with every setup cart, regardless of personal preferences.

- Clarity and overview: Through visual order, everything is immediately recognizable and ready for use.

- Faster handling: The ergonomics of the setup cart ensure intuitive use and faster processes.

Conclusion: Process optimization is worthwhile

Composition of the set-up terminal injection moulding

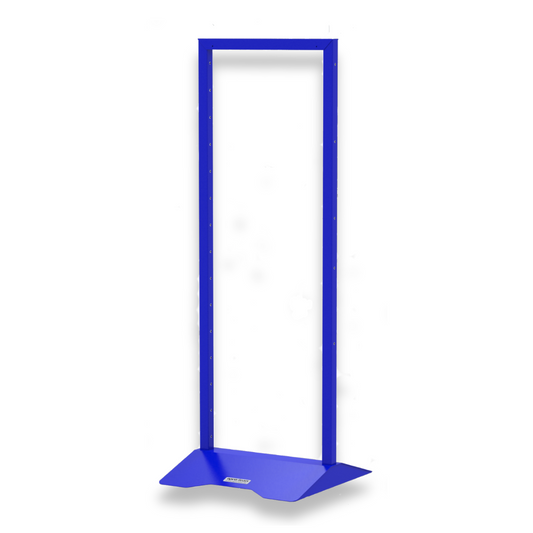

-

Basic frames

Regular price From €317,50 EURRegular priceUnit price / per -

Roller set

Regular price €79,65 EURRegular priceUnit price / per -

Handle module

Regular price €9,30 EURRegular priceUnit price / per -

Labeling sets Individual text

Regular price €79,65 EURRegular priceUnit price / per -

Drawers 2 x 100 mm

Regular price €252,50 EURRegular priceUnit price / per -

Drawer 200 mm

Regular price €190,00 EURRegular priceUnit price / per -

Paper dispenser

Regular price €50,90 EURRegular priceUnit price / per -

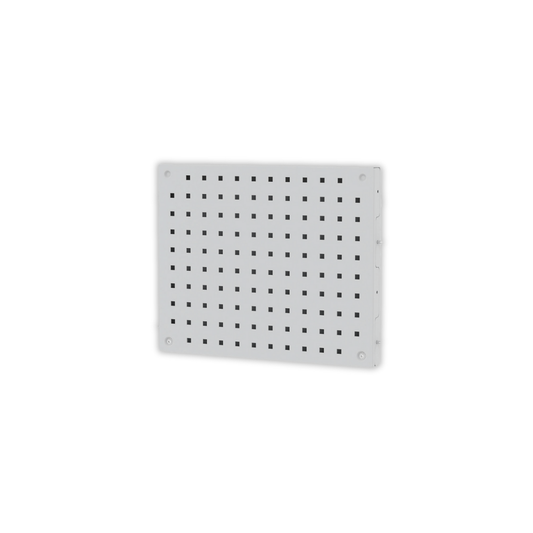

Grid plate 400 mm

Regular price €82,75 EURRegular priceUnit price / per -

Tool tray small

Regular price €63,70 EURRegular priceUnit price / per -

Trash can holder

Regular price €53,30 EURRegular priceUnit price / per -

Can / bottle holder

Regular price €25,30 EURRegular priceUnit price / per

1

/

of

11