Set-up station for automation

The challenges in injection moulding automation are many and varied. The set-up of removal robots in particular - especially the changing of end effectors such as grippers and vacuum cups - often harbours potential for optimisation. Long walking distances, confusing tool storage and cumbersome work processes delay the production process and cost valuable time. The set-up station offers an innovative solution that effectively addresses these challenges.

Get in touch with us:

Challenges in classic set-up practice

Injection moulding machines with automatic removal robots are the backbone of many production lines. However, in practice, those responsible repeatedly encounter the following problems:

- Long walking distances: Grippers and tools are often located in different places, which considerably increases set-up times.

- Unclear organisation: Tools and accessories are often scattered or stored in an unstructured manner.

- Decentralised conversions: Adjustments to grippers are made away from the machines, which means additional travelling and time losses.

The smart solution: set-up stations directly on the automation system

The introduction of the set-up station eliminates this inefficiency. The concept makes it possible to seamlessly integrate the entire set-up process into the production environment.

Advantages at a glance:

- Minimised walking distances: The set-up station is moved directly next to the automation system, reducing walking distances to a minimum. Maximum time saving!

- Optimised conversion: Grippers can be adjusted directly on site on a specialised work surface with a non-slip rubber mat.

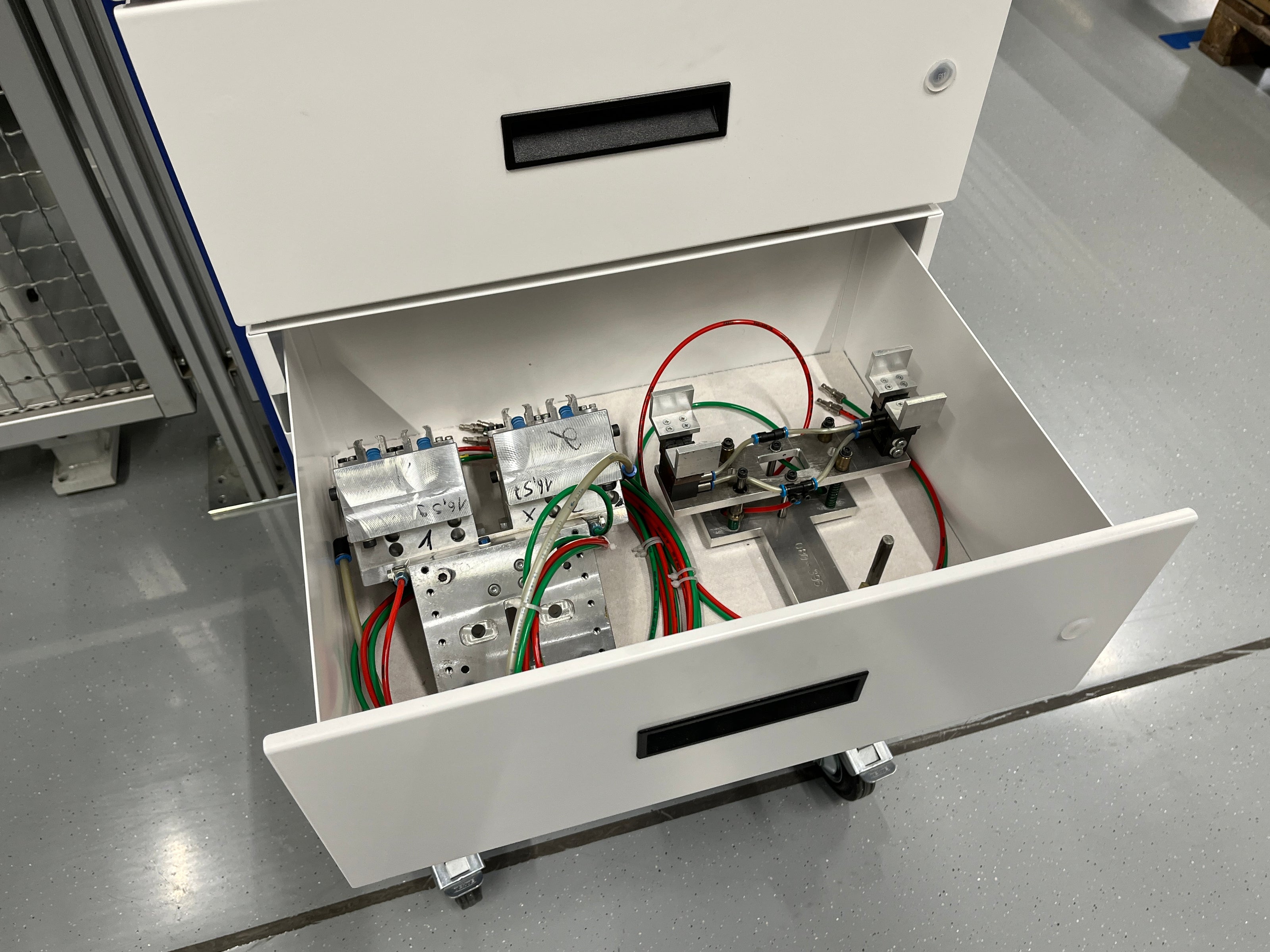

- Dust-protected storage: Drawer modules offer clear and protected storage of all grippers, customised to the requirements of the respective application.

Automation. - Tools to hand: All the necessary tools are clearly structured and directly available, eliminating search times and walking distances.

Process optimisation made easy

The set-up station significantly reduces set-up times and minimises machine downtimes. At the same time, employees benefit from a tidy and safe working environment.

Working environment.

The result: more efficient processes, reduced costs and higher productivity.

Conclusion: More efficiency through well thought-out solutions

The set-up station impressively demonstrates how targeted measures can make everyday work in injection moulding automation easier. By integrating this solution, companies benefit from shorter throughput times and a sustainable improvement in process quality.

Take advantage of the opportunities offered by modern automation and make your production future-proof - with innovative set-up concepts such as the set-up station.

Are you also looking for a solution for your processes?

Please feel free to contact us!

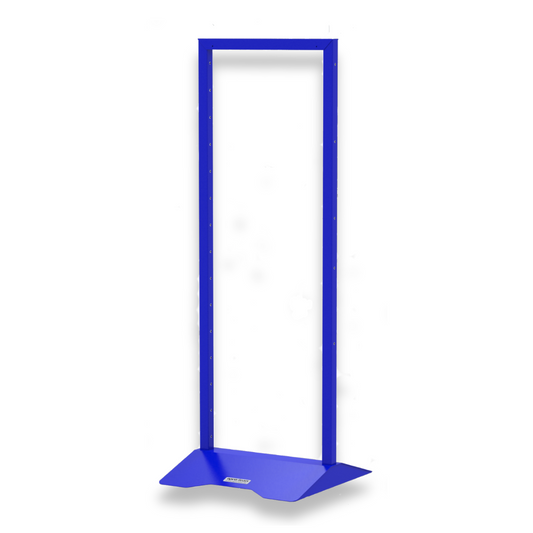

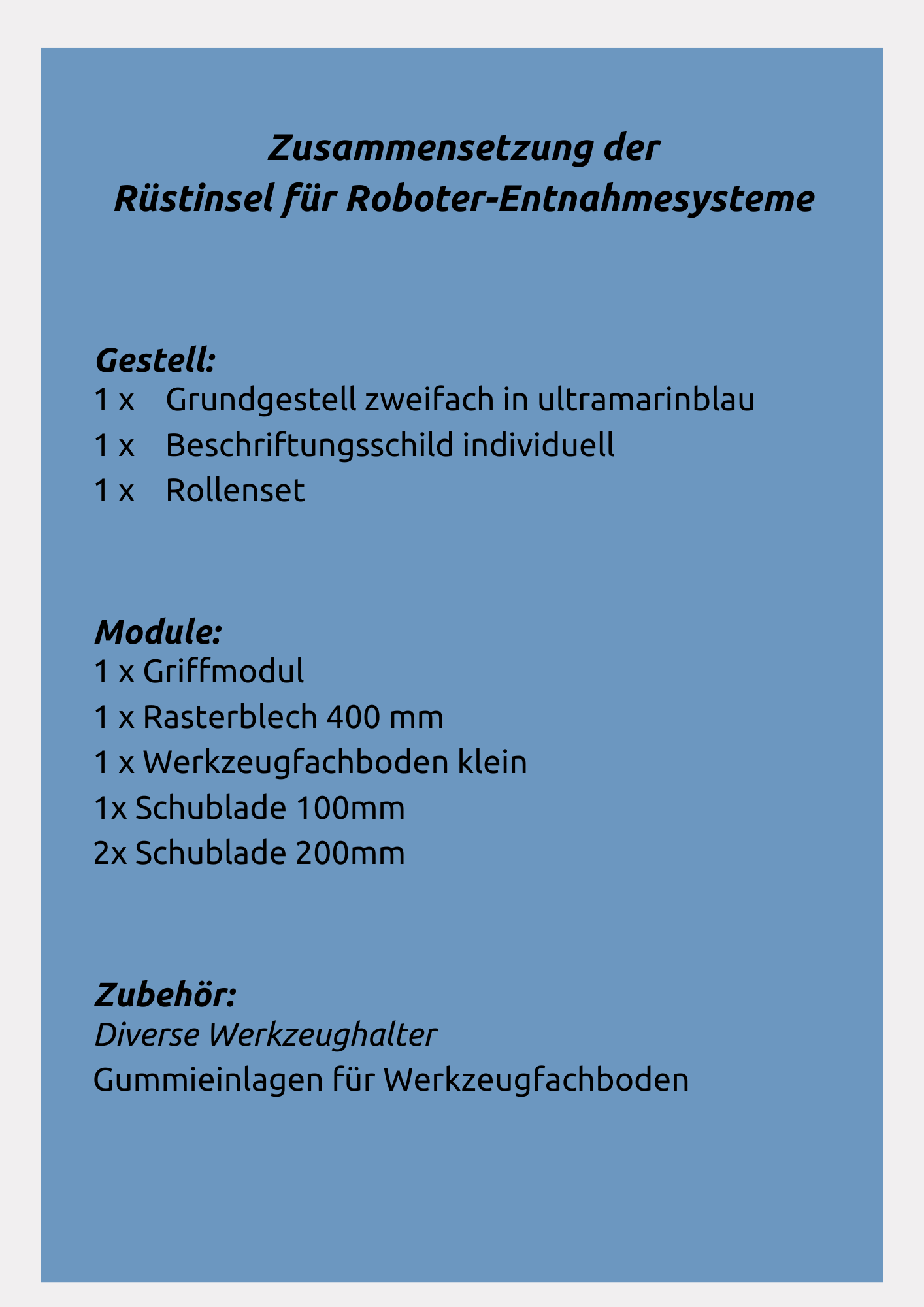

Composition of the set-up station for robot removal systems

-

Basic frames

Regular price From €317,50 EURRegular priceUnit price / per -

Roller set

Regular price €79,65 EURRegular priceUnit price / per -

Labeling sets Individual text

Regular price €79,65 EURRegular priceUnit price / per -

Tool tray small

Regular price €63,70 EURRegular priceUnit price / per -

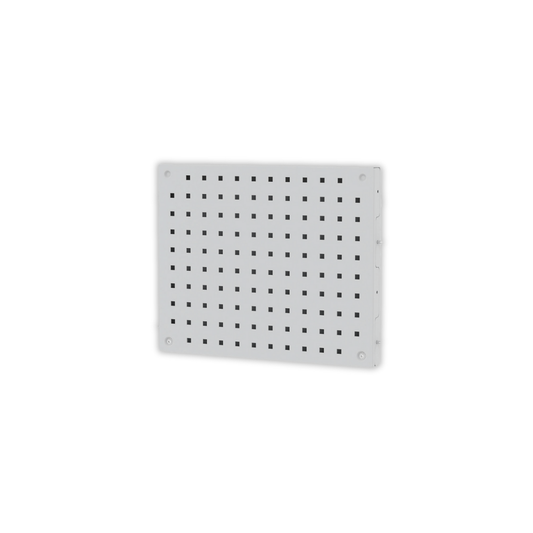

Grid plate 400 mm

Regular price €82,75 EURRegular priceUnit price / per -

Drawer 200 mm

Regular price €190,00 EURRegular priceUnit price / per -

Drawers 2 x 100 mm

Regular price €252,50 EURRegular priceUnit price / per

1

/

of

7